Car Tailgate Pacemaker

How Car Electric Tailgate Works?

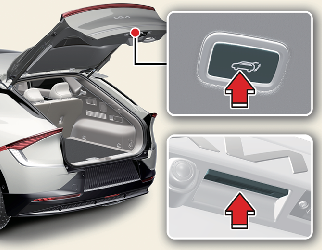

Electric tailgates, commonly known as power liftgates, enhance vehicle convenience by automating the opening and closing of the rear trunk. These systems typically utilize electric motors, often DC gear motors, to drive the tailgate’s movement. Activation can be achieved through various methods, including pressing a button on the vehicle, using a key fob, or employing hands-free sensors that detect a foot movement beneath the rear bumper.

The electric tailgate system comprises several key components:

Electric Motor: Provides the necessary torque to move the tailgate.

Transmission Mechanism: Converts the motor’s rotational motion into linear movement, facilitating the tailgate’s opening and closing.

Control Unit: Processes input signals from the user (e.g., button presses or sensor activations) and manages the motor’s operation accordingly.

Safety Sensors: Detect obstacles in the tailgate’s path to prevent injury or damage by stopping or reversing the movement if an obstruction is detected.

Manual Override: Allows for manual operation of the tailgate in case of system failure or when the vehicle’s battery is depleted.

The integration of these components ensures that the electric tailgate operates smoothly, providing users with a seamless and efficient experience.

How DC Gear Motor Works on Car Electric Tailgate?

In automotive electric tailgate systems, DC gear motors are essential for automating the opening and closing of the trunk. These motors are typically integrated into electric strut assemblies, which consist of an inner tube housing the motor and gearbox, and an outer tube containing a threaded nut. When activated, the DC gear motor drives a threaded spindle within the inner tube, causing the nut in the outer tube to move. This movement extends or retracts the strut, thereby opening or closing the tailgate. The gear mechanism ensures that the motor operates smoothly and efficiently, providing the necessary torque to handle the weight of the tailgate. Additionally, the system often includes safety features such as obstacle detection to prevent injury or damage during operation.

Advantages of DC Gear Motor Working in Car Electric Tailgate?

DC gear motors are integral to automotive electric tailgate systems, offering several advantages:

High Torque Output: They provide the necessary torque to lift and lower heavy tailgates, ensuring smooth operation.

Compact Design: Their small size allows for easy integration into the vehicle’s structure without compromising space.

Energy Efficiency: DC gear motors consume less power, contributing to overall vehicle energy efficiency.

Low Noise Operation: They operate quietly, enhancing the user experience by minimizing noise during tailgate movement.

Durability: Designed for automotive applications, they are built to withstand harsh conditions, ensuring long-term reliability.